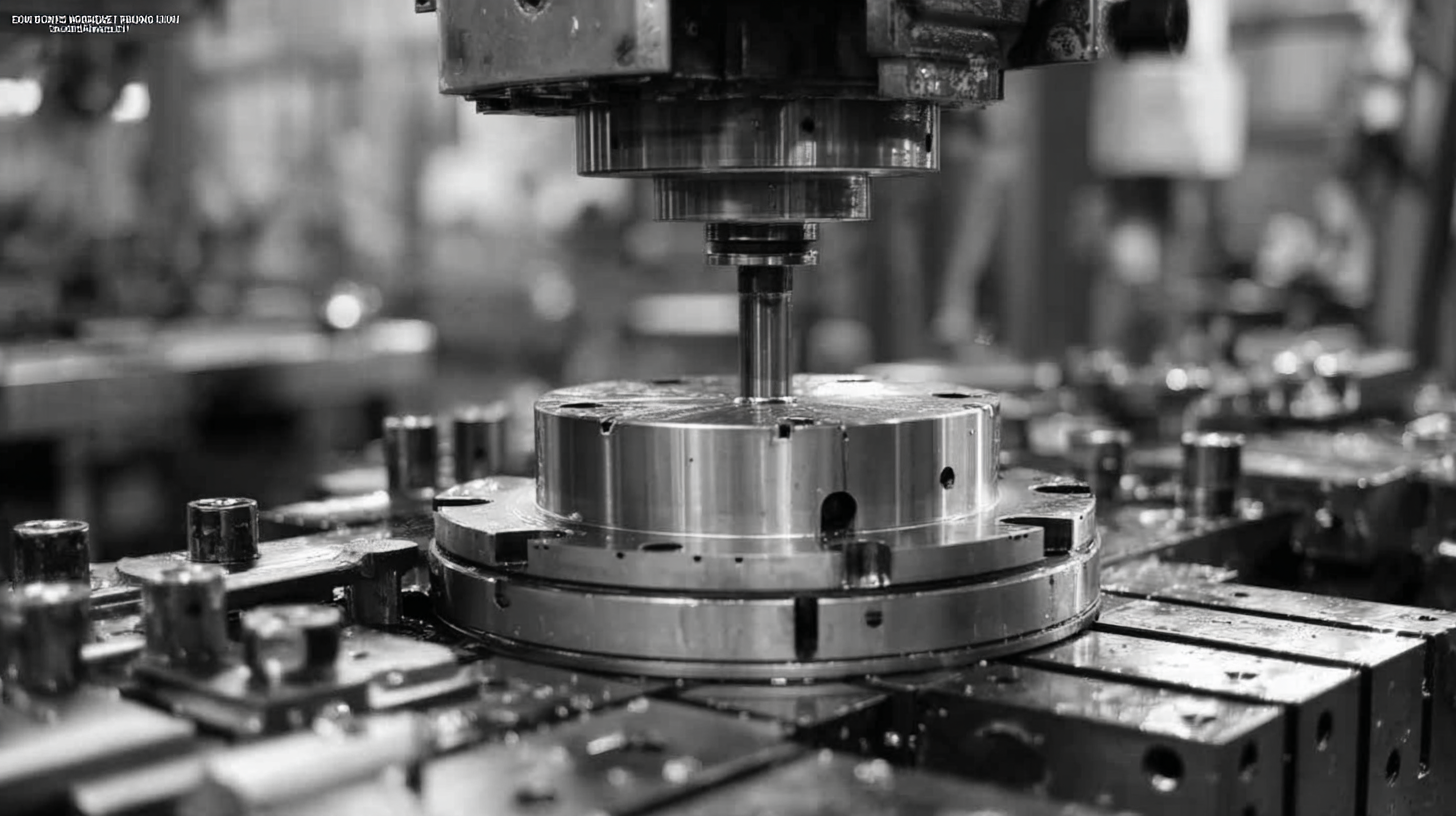

In today's competitive manufacturing landscape, optimizing your supply chain for CNC machined aluminum parts has become increasingly crucial. According to a recent report by Grand View Research, the global CNC machining market is expected to reach $100.8 billion by 2027, with aluminum parts being a significant driver due to their lightweight and high-strength properties.

As businesses look to improve efficiency and reduce costs, leveraging advanced supply chain strategies is essential. This includes sourcing materials strategically, fostering relationships with reliable suppliers, and implementing technology-driven solutions. By effectively managing these elements, companies can enhance production capabilities, reduce lead times, and ensure the timely delivery of CNC machined aluminum parts to meet customer demands.

As businesses look to improve efficiency and reduce costs, leveraging advanced supply chain strategies is essential. This includes sourcing materials strategically, fostering relationships with reliable suppliers, and implementing technology-driven solutions. By effectively managing these elements, companies can enhance production capabilities, reduce lead times, and ensure the timely delivery of CNC machined aluminum parts to meet customer demands.

Identifying key players in the CNC machined aluminum parts supply chain is essential for optimizing sourcing strategies. The modern supply chain for aluminum components typically consists of suppliers of raw materials, CNC machining service providers, and distributors. According to a recent report by Grand View Research, the global CNC machining market is projected to reach $100 billion by 2028, indicating significant growth opportunities for businesses looking to establish reliable partnerships within the supply chain.

Tip: When assessing potential suppliers, it’s crucial to evaluate their capabilities, certifications, and past performance. Look for ISO 9001 certification as it demonstrates a commitment to quality management systems. Additionally, consider their lead times, as timely delivery is crucial in maintaining production schedules.

Furthermore, leveraging technology can streamline communication among these key players, enhancing collaboration and efficiency. Tools like ERP (Enterprise Resource Planning) systems and supply chain management software help synchronize operations and provide real-time visibility into inventory levels and order statuses. According to a report by McKinsey, companies that invest in digital supply chain technologies can reduce inventory costs by up to 25%.

Tip: Regularly review and analyze supplier performance metrics to identify areas for improvement. Establishing strong relationships with key players ensures a resilient supply chain that can adapt to market fluctuations and demand changes effectively.

| Key Player Type | Role in Supply Chain | Location | Specialization | Average Lead Time (Days) |

|---|---|---|---|---|

| Material Suppliers | Provide raw aluminum materials | North America | Aluminum Alloys | 7 |

| CNC Machining Companies | Machining parts to specifications | Europe | Precision Components | 10 |

| Quality Control Inspectors | Ensure quality standards are met | Asia | Material Testing | 5 |

| Logistics Providers | Transport finished products | Global | Freight Shipping | 14 |

| End Users | Utilize CNC machined components | Various | Diverse Industries | Variable |

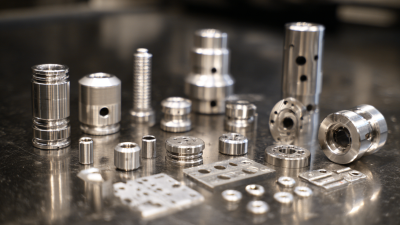

When sourcing CNC machined aluminum parts, assessing quality standards is paramount to ensure both performance and reliability. Establishing clear benchmarks for quality can help manufacturers avoid costly mistakes and delays. Essential factors include material specifications, tolerances, surface finishes, and any applicable industry certifications. Understanding these standards not only facilitates smoother communication with suppliers but also helps in evaluating their capabilities and ensuring compliance.

To further enhance the quality assurance process, companies should implement systematic inspections and testing protocols at various stages of production. This might involve first-article inspections, in-process checks, and final audits. Collaborating with suppliers who utilize advanced quality management systems can also fortify this effort. Regular audits and feedback mechanisms can promote transparency, helping businesses identify potential issues before they escalate. By prioritizing quality standards throughout the sourcing process, companies can secure superior CNC machined aluminum parts that meet their operational requirements and stand the test of time.

In today's fast-paced manufacturing landscape, leveraging technology is essential for optimizing your supply chain, especially when sourcing CNC machined aluminum parts. Integrating advanced software solutions can streamline processes, reduce lead times, and enhance communication among stakeholders. One effective strategy is to implement an integrated supply chain management system that provides real-time tracking and analytics. This technology allows for better forecasting and helps anticipate potential disruptions, ensuring a more resilient supply chain.

To further enhance efficiency, consider using cloud-based collaboration tools. These tools enable seamless communication between suppliers and manufacturers, making it easier to share data, specifications, and updates. This not only accelerates decision-making but also minimizes errors and misunderstandings.

Additionally, investing in automation for inventory management can significantly reduce manual workload and improve accuracy. By utilizing automated systems to track inventory levels and reorder supplies as needed, companies can maintain optimal stock levels and ensure timely production. Embracing these technological advancements can position your supply chain for greater efficiency and scalability in the competitive market of CNC machined aluminum parts.

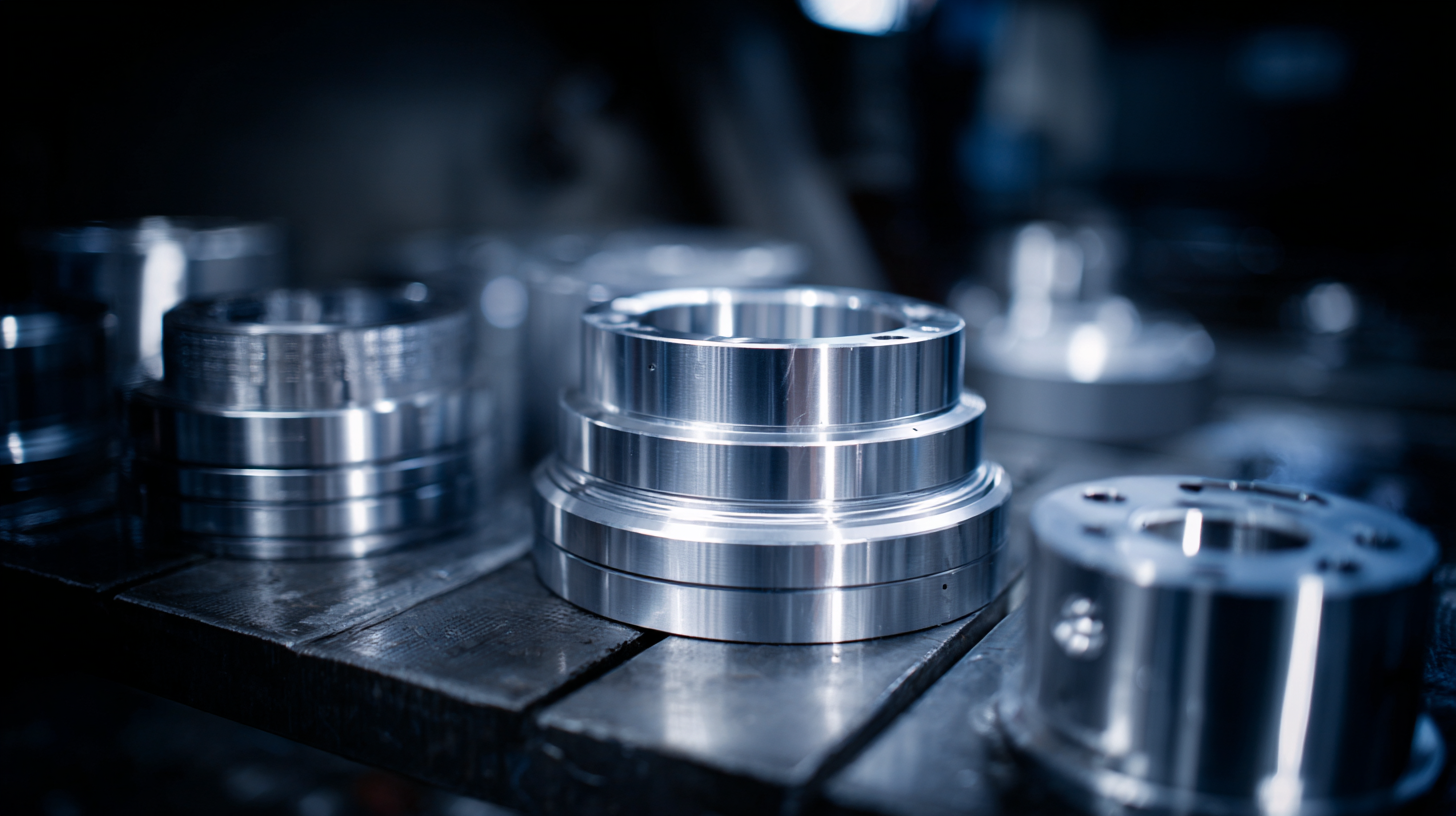

When sourcing CNC machined aluminum parts, implementing cost-effective procurement strategies is crucial to optimize your supply chain. Start by establishing strong relationships with suppliers who specialize in aluminum machining. This not only fosters trust but also opens doors to better pricing and favorable terms. Regularly engaging with your suppliers allows for transparent communication, enabling you to address any issues quickly and negotiate volume discounts or long-term contracts that can significantly lower costs.

Additionally, consider using a just-in-time (JIT) inventory system to reduce overhead and minimize waste. By synchronizing your production schedules with supplier deliveries, you can avoid excess inventory costs while ensuring you have the necessary parts when needed. Utilizing data analytics can also enhance decision-making, helping you identify trends and forecast demand more accurately. This proactive approach will allow you to make more informed purchasing decisions, ultimately leading to a more resilient and cost-efficient supply chain for your aluminum parts sourcing.

Collaboration with suppliers is crucial for optimizing the sourcing of CNC machined aluminum parts. Establishing strong relationships with your suppliers can lead to mutual benefits, including improved quality, increased efficiency, and cost savings. One key tip is to engage in regular communication. Set up weekly or bi-weekly meetings to discuss project updates, quality concerns, and design modifications. This fosters transparency and encourages suppliers to share valuable insights that can enhance the production process.

Another important aspect of collaboration is aligning your business goals with your suppliers’ capacities and capabilities. Share your long-term objectives and seek feedback on how suppliers can support these goals. By involving them in the planning stages, you can optimize lead times and minimize disruptions. Additionally, consider implementing a collaborative software tool that allows for real-time data sharing and inventory tracking, further streamlining the sourcing process.

Lastly, incentivize suppliers to innovate. Create a reward system that encourages them to propose design improvements or process efficiencies. This not only fosters a culture of innovation but also strengthens the partnership, resulting in better outcomes for both parties. By enhancing collaboration, you can effectively optimize your supply chain for CNC machined aluminum parts.