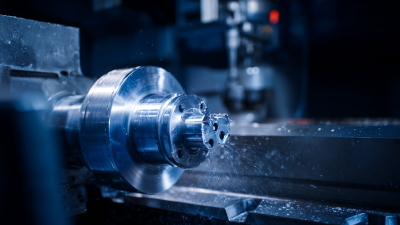

In today's competitive manufacturing landscape, the importance of quality Metal Lathe Parts cannot be overstated. According to a report by MarketsandMarkets, the global metalworking industry is anticipated to reach USD 1,058.7 billion by 2025, underscoring the growing demand for precision components across various sectors. Utilizing high-quality lathe parts can significantly enhance production efficiency, reduce waste, and ensure consistency in output. A study by the National Institute of Standards and Technology (NIST) found that companies investing in top-tier machinery and components see productivity gains of up to 30%. This not only leads to faster turnaround times but also helps in maintaining strict quality control standards, ultimately resulting in increased customer satisfaction. Thus, understanding the advantages of selecting premium Metal Lathe Parts is critical for businesses aiming to maximize efficiency and stay ahead in the rapidly evolving market.

Precision engineering plays a pivotal role in the performance and longevity of metal lathe parts. When crafting components that will endure high speeds and heavy loads, the precision involved in their manufacturing cannot be overstated. High-quality metal lathe parts are designed to exact specifications, ensuring that each piece fits flawlessly into the overall machinery. This level of accuracy minimizes the risk of wear and tear, leading to fewer operational disruptions and extending the lifespan of the equipment.

Precision engineering plays a pivotal role in the performance and longevity of metal lathe parts. When crafting components that will endure high speeds and heavy loads, the precision involved in their manufacturing cannot be overstated. High-quality metal lathe parts are designed to exact specifications, ensuring that each piece fits flawlessly into the overall machinery. This level of accuracy minimizes the risk of wear and tear, leading to fewer operational disruptions and extending the lifespan of the equipment.

Moreover, utilizing precision-engineered lathe parts contributes significantly to the efficiency of manufacturing processes. When parts are manufactured with meticulous attention to detail, they work harmoniously within the lathe, resulting in smoother operations and improved output. As a result, businesses can achieve higher production rates while maintaining product quality. Investing in top-notch metal lathe parts not only enhances immediate project outcomes but also fosters long-term reliability and productivity in various machining applications.

When sourcing metal lathe parts for your projects, the balance between quality and cost can present notable challenges. Often, the temptation to prioritize lower prices can lead to compromises on quality, resulting in premature wear or failures that can derail your projects. Understanding the long-term implications of these choices can help you make a more informed decision.

Tip 1: Always evaluate the reputation of your suppliers. A supplier known for high-quality parts may charge more upfront, but their products can ultimately save you time and money through reduced downtime and maintenance. Investing in a reliable supplier means investing in the longevity of your machinery.

Tip 2: Conduct material inspections before purchasing. Look for certifications and reviews that attest to the quality of the metal used in the lathe parts. This due diligence will help ensure that you are not just getting a great price but also parts that can withstand the demands of your projects.

By prioritizing quality, you set the foundation for efficient and successful project outcomes, making it essential to navigate the cost-quality conundrum judiciously.

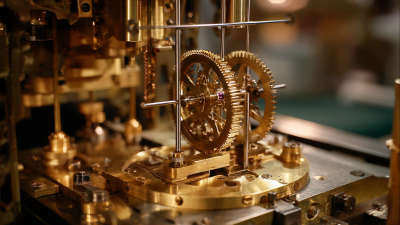

Selecting the right materials for metal lathe parts is crucial to maximize efficiency and enhance the longevity of your projects. Just as substrate choice significantly influences solar panel performance, the materials utilized in machining can greatly affect the functionality and durability of the parts produced. High-quality metals, like stainless steel or aluminum alloys, not only provide superior strength and resistance to wear and corrosion but also contribute to smoother operation and less frequent maintenance.

The innovation in material technology parallels trends seen in other industries, such as the development of sustainable building materials and natural fiber composites. These advances demonstrate a growing awareness of how material attributes play a foundational role in performance outcomes. By opting for quality metal lathe parts, not only do you improve the precision and reliability of your machining processes, but you also create components that stand the test of time, similar to the advantages seen with advanced materials in renewable energy applications and construction. Choosing wisely is not just about immediate results; it paves the way for future efficiency and sustainability.

When embarking on metalworking projects, the choice of components can significantly impact overall efficiency. Quality metal lathe parts not only enhance the precision of your work but also reduce the frequency of repairs and maintenance, allowing you to focus your energies on creativity and production. Using inferior parts may save money in the short term but often leads to complications that can derail a project, ultimately costing more in time and resources.

When embarking on metalworking projects, the choice of components can significantly impact overall efficiency. Quality metal lathe parts not only enhance the precision of your work but also reduce the frequency of repairs and maintenance, allowing you to focus your energies on creativity and production. Using inferior parts may save money in the short term but often leads to complications that can derail a project, ultimately costing more in time and resources.

Tip 1: Invest in reputable brands that are known for durability and performance. While it might seem prudent to opt for cheaper alternatives, the long-term benefits of high-quality parts will streamline your workflow and save you from potential setbacks.

Tip 2: Regularly assess and upgrade your toolset. Even if your current lathe parts seem functional, advancements in technology might offer features that enhance efficiency. Staying updated with the latest innovations can provide you with a competitive edge.

By prioritizing quality components, you ensure that your projects are executed efficiently, reducing downtime and enhancing productivity. Quality lathe parts empower you to achieve your vision with precision and reliability.

When it comes to metal lathe projects, the quality of your lathe parts can significantly impact efficiency and output. Low-quality lathe parts are often associated with increased wear and tear on machinery, which can lead to costly downtime. According to a report by the Manufacturing Institute, machinery malfunctions due to inferior components can increase operational costs by up to 30%. Additionally, low-quality parts can lead to inaccuracies in production, causing high rejection rates; studies indicate that subpar parts may contribute to a 15% increase in defective workpieces.

Troubleshooting common issues with low-quality lathe parts often involves addressing alignment and vibration problems. For example, improper alignment can cause uneven wear on tools, which affects the overall finish and precision of the machined components. The American Society of Mechanical Engineers (ASME) highlights that using high-quality components reduces the likelihood of such issues, thereby streamlining the machining process. By investing in superior metal lathe parts, manufacturers can not only enhance productivity but also prolong their machinery's lifespan, ultimately leading to higher-quality outputs and improved profitability.