In the rapidly evolving landscape of manufacturing, the future of Metal Parts is poised for remarkable advancements, driven by innovative technologies and processes. According to a report by MarketsandMarkets, the global metal parts market is projected to grow at a compound annual growth rate (CAGR) of 15% from 2020 to 2025, highlighting significant shifts in industry dynamics. Key factors fueling this growth include the rising demand for lightweight and high-strength components in sectors such as automotive and aerospace, alongside the increasing adoption of additive manufacturing and automated production methods. As manufacturers seek to enhance efficiency and reduce costs, embracing cutting-edge solutions becomes essential. This exploration into the innovations shaping the Metal Parts industry not only underscores the importance of adapting to technological changes but also emphasizes the potential for sustainable practices that could redefine manufacturing standards in the years to come.

In the rapidly evolving landscape of manufacturing, the future of Metal Parts is poised for remarkable advancements, driven by innovative technologies and processes. According to a report by MarketsandMarkets, the global metal parts market is projected to grow at a compound annual growth rate (CAGR) of 15% from 2020 to 2025, highlighting significant shifts in industry dynamics. Key factors fueling this growth include the rising demand for lightweight and high-strength components in sectors such as automotive and aerospace, alongside the increasing adoption of additive manufacturing and automated production methods. As manufacturers seek to enhance efficiency and reduce costs, embracing cutting-edge solutions becomes essential. This exploration into the innovations shaping the Metal Parts industry not only underscores the importance of adapting to technological changes but also emphasizes the potential for sustainable practices that could redefine manufacturing standards in the years to come.

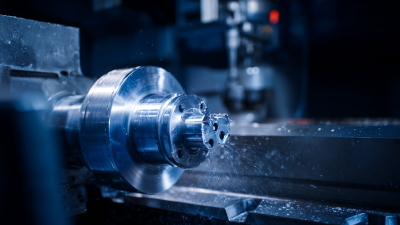

Innovative manufacturing techniques are fundamentally transforming the metal parts industry, paving the way for significant growth projected at 15% by 2025. One of the most notable advancements is the rise of additive manufacturing, often referred to as 3D printing. This technology allows for complex geometries that were previously impossible to achieve with traditional methods, resulting in lighter and more efficient metal components. By enabling rapid prototyping and reducing material waste, additive manufacturing not only accelerates the production process but also fosters sustainability in the metal fabrication sector.

Another key innovation driving the evolution of metal parts is the integration of automation and robotics in manufacturing processes. Automated systems enhance precision and consistency while simultaneously reducing labor costs and human error. With the advent of smart manufacturing and Industry 4.0 principles, manufacturers are leveraging data analytics and the Internet of Things (IoT) to optimize production lines. These technologies enable real-time monitoring and predictive maintenance, leading to increased operational efficiency and the ability to respond swiftly to market demands. As these innovative techniques continue to mature, the future of the metal parts industry appears not only promising but also essential for meeting the challenges of modern manufacturing.

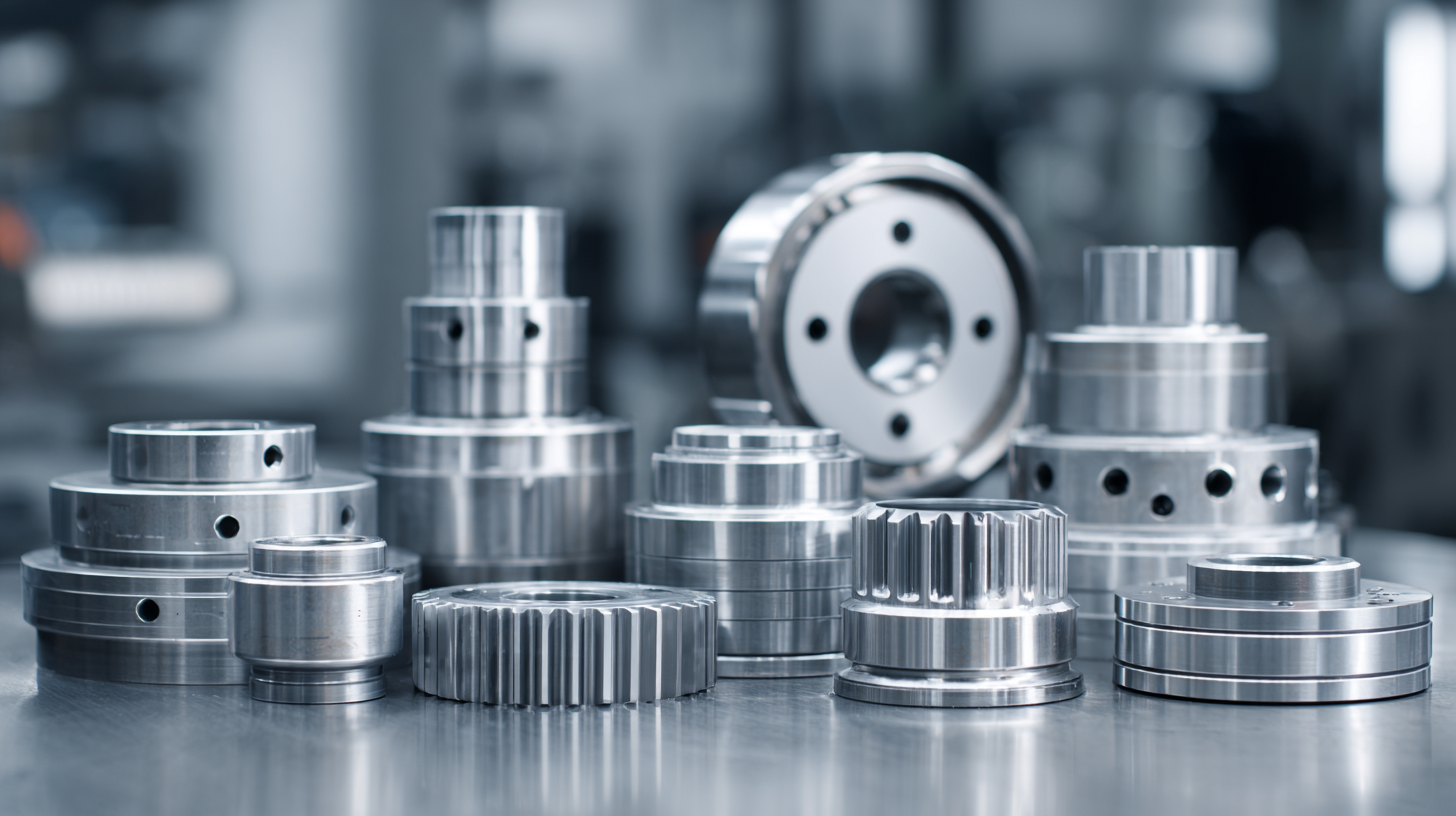

The future of metal parts production is being shaped by innovative materials that enhance efficiency and performance across various industries. Recent forecasts indicate that the market for carbon fiber materials used in aerospace applications will continue to expand significantly, with its growing adoption boosting overall production capabilities. Carbon fiber, known for its exceptional strength-to-weight ratio, is increasingly utilized in aircraft structures, leading to improved fuel efficiency and reduced emissions—crucial factors for the aerospace industry's sustainability goals.

In addition to carbon fiber, aluminum silicon carbide (ALSIC) is emerging as a vital material for applications in electronics, aerospace, and defense. This advanced metal matrix composite combines the lightweight properties of aluminum with the durability of silicon carbide, making it an ideal choice for high-performance applications. As industries increasingly shift towards materials that offer both performance and environmental benefits, the global market for ALSIC and similar innovations is projected to experience robust growth. Reports suggest that such advancements in materials technology are driving a projected 15% growth in the metal parts industry by 2025, underscoring the importance of innovation in maintaining competitive advantage.

| Material Type | Growth Rate (2023-2025) | Key Innovations | Application Areas | Efficiency Gains (%) |

|---|---|---|---|---|

| Aluminum Alloys | 10% | Advanced Heat Treatment | Aerospace, Automotive | 15% |

| Titanium Alloys | 12% | Additive Manufacturing Techniques | Medical, Aerospace | 20% |

| High-Strength Steels | 8% | Micro-alloying Technology | Construction, Automotive | 10% |

| Magnesium Alloys | 15% | Novel Alloy Development | Automotive, Electronics | 25% |

| Copper Alloys | 9% | Enhanced Conductivity Treatments | Electrical, Military | 12% |

The integration of automation and artificial intelligence (AI) in metal parts manufacturing is set to redefine the industry's landscape, fueling its projected 15% growth by 2025. With emerging technologies such as die casting leading the charge, manufacturers are increasingly adopting lightweight materials and sustainable practices that not only enhance product performance but also improve operational efficiency. Industry reports highlight that the market for die-cast parts is evolving rapidly, establishing itself as a crucial player in innovation across various manufacturing sectors.

The establishment of AI-driven centers, like those focusing on materials innovation, demonstrates the commitment of the sector to leverage cutting-edge technologies. AI is being utilized for predictive maintenance, and generative design, and is increasingly prevalent in processes across the manufacturing ecosystem. Experts suggest that AI applications can significantly optimize workflows, thereby driving down operational costs and improving product quality.

Predictions indicate that markets such as sheet metal fabrication services are expected to grow significantly, reaching a valuation of USD 33.31 billion by 2034, underscoring the impact of technological advancements in shaping future manufacturing paradigms.

The metal parts industry is undergoing a significant transformation driven by sustainability trends that are poised to reshape its future. By 2025, the industry is projected to grow by 15%, reflecting an increasing demand for environmentally responsible manufacturing practices. Reports indicate that the steel market, a crucial component of metal parts, is expected to face challenges due to overcapacity, which may hinder its sustainable transition. However, innovations such as hybrid steel drums, developed in response to evolving regulatory standards, are creating new opportunities for growth.

As manufacturers focus on sustainability, it is essential to understand consumer preferences towards packaging materials, which vary across different regions. This nuanced understanding can help businesses align their practices with market demands and enhance their competitive edge. Tips for companies include investing in sustainable materials, adopting advanced production technologies like metal 3D printing, and openly communicating their sustainability efforts to consumers.

Furthermore, the aerospace parts manufacturing market, valued at around USD 936 billion in 2024, is driven by sustainability trends alongside increasing aircraft deliveries and defense investments. This segment exemplifies how sustainability serves as a catalyst for innovation, ensuring that companies can thrive in an evolving marketplace. Emphasizing sustainable practices not only meets regulatory standards but also attracts environmentally-conscious consumers, setting the stage for long-term success.

Emerging markets are poised to play a pivotal role in the growth of the metal parts industry, contributing significantly to the projected 15% growth by 2025. Countries like India, Brazil, and Vietnam are experiencing rapid industrialization and increased demand for metal components across various sectors such as automotive, aerospace, and construction. This shift not only highlights the potential for revenue increase but also addresses the necessity for customized solutions that cater to the unique needs of these markets.

Tip: To effectively penetrate emerging markets, companies should invest in understanding local market dynamics, regulatory environments, and consumer preferences. This localized approach can lead to tailored products that resonate with regional demands, improving overall market adoption.

As businesses harness technology and innovation, the strategic focus should also be on sustainable manufacturing practices. The emphasis on environmentally friendly production can attract new clients who prioritize corporate responsibility, further driving growth in these burgeoning markets. Collaboration with local firms can facilitate market entry by leveraging existing networks and expertise.

Tip: Establish partnerships with local businesses to enhance your supply chain efficiency and gain insights into customer behavior, ensuring a more successful market entry strategy.