The global demand for steel parts has surged in recent years, primarily driven by the booming automotive and construction industries. According to the World Steel Association, steel production reached approximately 1.85 billion metric tons in 2022, highlighting its crucial role in various manufacturing sectors. As industries increasingly prioritize durability and efficiency, sourcing high-quality steel parts has become essential for maintaining competitive advantage. However, navigating the complexities of material selection, supplier reliability, and cost management can be challenging for manufacturers.

This blog aims to provide you with seven expert tips for sourcing high-quality steel parts, ensuring you make informed decisions that enhance product performance and longevity.

When it comes to manufacturing, the quality of steel parts can significantly influence the overall success of a project. High-quality steel parts lead to enhanced durability, performance, and efficiency in production. According to a report by MarketsandMarkets, the global steel market is expected to reach over $1 trillion by 2026, emphasizing the critical role these materials play in various industries. Choosing the right steel can prevent unexpected failures and costly downtime, making it imperative for manufacturers to prioritize source quality.

One expert tip for sourcing quality steel parts is to establish strong relationships with reputable suppliers. Networking within the industry can provide insights into suppliers' reliability and product quality. Additionally, always request certifications and test reports, which can provide assurance of the material's compliance with international standards. A study by ASTM International suggests that up to 30% of manufacturing failures can be attributed to poor material quality, underscoring the need for diligence in supplier selection.

Another important factor is to stay informed about advancements in steel manufacturing techniques. Utilizing suppliers that invest in modern production technologies can lead to superior products. For instance, advanced metallurgical processes can enhance the strength and resilience of steel, which is crucial for high-stress applications. By integrating these tips into your sourcing strategy, you can enhance your manufacturing outcomes and maintain a competitive edge in the market.

| Tip No. | Expert Tip | Importance | Example of Application |

|---|---|---|---|

| 1 | Verify Material Specifications | Ensures compliance with industry standards | Used in automotive parts for safety |

| 2 | Conduct Supplier Audits | Builds trust and ensures quality systems are in place | Applied in aerospace components |

| 3 | Request Material Certification | Confirms the quality of raw materials | Essential for medical equipment manufacturing |

| 4 | Review Manufacturing Processes | Identifies potential quality issues early | Critical in precision engineering projects |

| 5 | Ask for Reference Projects | Gauges a supplier's experience and reliability | Valuable in construction projects |

| 6 | Evaluate Quality Control Procedures | Ensures products meet specs during manufacturing | Used in electronics component production |

| 7 | Check for Industry Certifications | Validates suppliers’ adherence to standards | Important for supply chains in pharmaceuticals |

When sourcing high-quality steel parts, understanding the key characteristics to look for is essential. Firstly, the material's grade and composition play a pivotal role in determining its strength and durability. High-quality steel typically adheres to established standards, such as ASTM or ISO certifications, which indicate its tensile strength, yield strength, and resistance to corrosion. Ensure that the steel you consider meets the specific requirements of your project, as different applications may demand various grades.

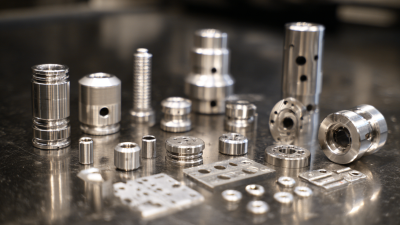

Another crucial characteristic to evaluate is the manufacturing process. A reliable supplier will use advanced machining techniques and quality control measures to produce parts that not only meet specifications but also maintain consistency across production batches. Additionally, attention should be paid to the supplier’s reputation and their commitment to customer service. Engaging with suppliers who prioritize transparency in their processes, offer detailed product information, and provide a robust warranty can significantly enhance your sourcing experience and final product quality.

When sourcing high-quality steel parts, effectively evaluating steel suppliers is crucial to ensure that the materials meet your specific needs. One of the top methods for assessment is conducting a comprehensive review of the suppliers' certifications and standards. Ensure that your potential suppliers comply with industry standards, such as ISO 9001, which indicates a commitment to quality management. Checking for other relevant certifications can provide insights into their manufacturing processes and quality assurance practices.

Another critical method is to request samples of the steel parts before placing larger orders. This allows you to conduct a thorough inspection and testing of the materials, assessing factors such as tensile strength, corrosion resistance, and overall durability. By comparing samples from different suppliers, you can make informed decisions based on objective quality metrics rather than solely on price. Additionally, establishing direct communication with suppliers to discuss their production capabilities, lead times, and after-sales support can further solidify your confidence in their ability to meet your steel part requirements.

This bar chart illustrates the quality scores of various steel suppliers based on expert evaluations. The scores are based on factors such as material durability, precision, and production standards.

When it comes to procuring steel parts, avoiding common pitfalls can make a significant difference in overall project success. One of the most frequent mistakes is failing to conduct proper supplier research. Many companies jump into a transaction without vetting potential suppliers for quality, certifications, and reliability. This oversight can lead to subpar parts that compromise product integrity and elevate costs due to necessary replacements or repairs.

Another prevalent misstep is neglecting to clarify specifications. Often, buyers assume that their requirements are understood, which can result in misunderstandings and incorrect parts being delivered. Clear communication regarding material grades, tolerances, and finishes is crucial. Additionally, overlooking the importance of lead times and delivery schedules can disrupt production plans, so establishing realistic timelines with suppliers is essential for smooth operations. By avoiding these errors, companies can enhance their procurement strategies and ensure they source high-quality steel parts effectively.

In recent years, the steel sourcing industry has witnessed significant changes driven by technological advancements and evolving market dynamics. According to a report by Research and Markets, the global steel market is projected to grow at a CAGR of 2.5% from 2021 to 2026, highlighting the increasing demand for high-quality steel parts across various sectors. This growth is primarily fueled by the automotive and construction industries, where high-strength and lightweight steel components are essential for enhancing performance and sustainability.

Another pivotal trend shaping the future of steel sourcing is the shift towards sustainable practices. The World Steel Association reports that the steel industry accounts for approximately 7% of global CO2 emissions, pushing manufacturers to adopt greener methods. Innovations such as electric arc furnaces and the use of recycled materials are becoming more prevalent, as companies look to reduce their carbon footprints and meet stricter environmental regulations. Consequently, sourcing high-quality steel parts is not only about performance but also about ensuring that these materials align with sustainability goals, which are increasingly critical for both consumers and producers in the competitive market landscape.