In today's manufacturing landscape, the importance of selecting the right Precision Metal Parts cannot be overstated. As industries evolve, the demand for high-quality metal components continues to soar, with the global precision metal parts market projected to reach $84.1 billion by 2025, according to a report by Grand View Research. This surge is driven by advancements in technology and increased applications across various sectors, including automotive, aerospace, and electronics. Selecting the right precision metal parts is crucial to ensuring product performance, longevity, and cost-effectiveness.

Understanding the intricacies involved in this selection process can significantly impact project outcomes, making it an essential consideration for engineers and project managers alike. This guide aims to equip you with the necessary knowledge to navigate the complexities of choosing the best precision metal components for your specific needs.

Precision metal parts play a critical role in engineering projects, impacting functionality and reliability. These components are often the backbone of intricate systems in industries such as automotive, aerospace, and electronics. The high level of accuracy required in these sectors means that even the slightest deviation in dimensions can lead to performance failures, increased costs, and unsafe conditions. Therefore, understanding the specifications and tolerances of precision metal parts is essential for engineers when designing and selecting materials for their projects.

Moreover, the importance of precision extends beyond mere functionality; it also affects the overall efficiency and lifespan of the finished products. Quality precision parts contribute to smoother operations, reduced wear and tear, and lower maintenance costs for the end user. By prioritizing the selection of high-quality materials and manufacturing processes, engineers can ensure that their projects not only meet design requirements but also exceed expectations in durability and performance. Ultimately, investing time and resources in understanding precision metal parts will lead to innovative solutions and successful engineering outcomes.

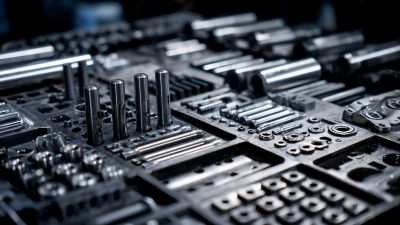

| Part Type | Material | Tolerances (mm) | Application | Lead Time (Weeks) |

|---|---|---|---|---|

| Bracket | Aluminum 6061 | ±0.1 | Structural Support | 2 |

| Gear | Steel | ±0.05 | Mechanical Transmission | 4 |

| Shaft | Stainless Steel | ±0.02 | Rotating Assembly | 3 |

| Plate | Carbon Steel | ±0.2 | Base Structure | 1 |

| Bolt | Alloy Steel | ±0.1 | Fastening Parts | 2 |

When selecting precision metal parts for your projects, several key factors must be considered to ensure quality and performance. The precision metal parts market, particularly in sectors like aerospace, medical devices, electronics, and automotive, is driven by the demand for components that meet stringent specifications. According to recent industry reports, the global market for precision metal components is projected to reach USD 137.61 billion by 2027, growing at a CAGR of 6.46%. This growth underscores the importance of manufacturing processes such as CNC machining, electrical discharge machining, and laser cutting in producing high-quality parts.

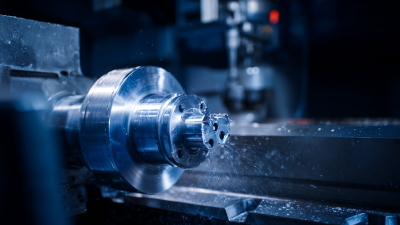

One of the foremost considerations when choosing precision metal parts is the material selection. Metals such as stainless steel, aluminum, and titanium are often used due to their strength, durability, and corrosion resistance. Additionally, the manufacturing process plays a critical role in achieving the desired specifications. For instance, CNC machining allows for intricate designs and tight tolerances that are essential in applications like aerospace, where precision is crucial for safety and performance. The right manufacturing process can significantly impact the cost-effectiveness and reliability of the components, making it imperative to evaluate each option carefully based on project requirements.

When it comes to precision metal parts, understanding the various types and their specific applications across industries is crucial for successful project outcomes. One prominent category includes components made through Metal Injection Molding (MIM), which is particularly beneficial for complex geometries in high-volume production. MIM is widely utilized in sectors such as automotive, electronics, and medical devices, thanks to its ability to produce intricate parts with excellent tolerances.

Another significant type of precision metal part is derived from specialized metal powders, particularly in the context of additive manufacturing. The growing demand for these powders reflects the industry's shift towards more customized solutions and enhances the ability to create lightweight yet durable components. Industries ranging from aerospace to consumer electronics are increasingly leveraging this technology to improve efficiency and performance in their applications. Understanding these options allows manufacturers and designers to select the most appropriate materials and processes for their specific needs, paving the way for innovation and competitive advantage.

When selecting precision metal parts for your projects, evaluating the quality and specifications of these components is crucial. First, consider the material properties, such as tensile strength, corrosion resistance, and thermal stability. High-quality metal parts should meet the specific demands of your application, whether that involves extreme temperatures or exposure to harsh chemicals. Request certificates of compliance or material test reports from suppliers to ensure that the materials used adhere to industry standards.

When selecting precision metal parts for your projects, evaluating the quality and specifications of these components is crucial. First, consider the material properties, such as tensile strength, corrosion resistance, and thermal stability. High-quality metal parts should meet the specific demands of your application, whether that involves extreme temperatures or exposure to harsh chemicals. Request certificates of compliance or material test reports from suppliers to ensure that the materials used adhere to industry standards.

Additionally, examine the manufacturing process and tolerances associated with the metal parts. Precision machining techniques, such as CNC milling or turning, often yield the most accurate dimensions and fit. It's essential to verify the tolerances provided by the manufacturer against your project requirements to avoid any performance issues. Lastly, evaluate the supplier’s reputation and experience in the industry, as this can often reflect the quality of their products and their ability to support your needs throughout the project lifecycle.

When it comes to sourcing custom precision metal parts, effective collaboration with suppliers is crucial to the success of your project. Start by articulating your project requirements clearly, including dimensions, materials, tolerances, and any specific finishes. This initial communication lays the groundwork for a productive relationship and helps suppliers understand your unique needs. Be open to their suggestions, as experienced suppliers can offer insights that may enhance your design or reduce production costs.

Another key aspect of collaboration is establishing a timeline. Make sure to discuss lead times and any potential delays upfront. This transparency helps manage expectations on both sides and ensures that your project stays on track. Regular check-ins during the production process can also foster a collaborative environment. Use these opportunities to discuss progress, address any concerns, and make adjustments if necessary, creating a partnership aimed at delivering high-quality results that meet your specifications.

This bar chart depicts the importance of various factors when selecting precision metal parts for projects, based on survey results from engineering professionals.