In the fast-evolving landscape of modern manufacturing, Aluminum CNC Machining Parts have emerged as a cornerstone of production efficiency and precision. According to a report by MarketsandMarkets, the CNC machining market is projected to reach $100 billion by 2026, with aluminum parts experiencing a significant surge in demand due to their lightweight, corrosion resistance, and machinability. In industries ranging from aerospace to automotive, the ability to produce intricate aluminum components with exacting accuracy not only enhances product performance but also drives cost-effectiveness. This guide aims to unlock the potential of Aluminum CNC Machining Parts, offering essential insights and practical tips that will enable manufacturers to optimize their processes and stay competitive in a market increasingly reliant on advanced manufacturing technologies.

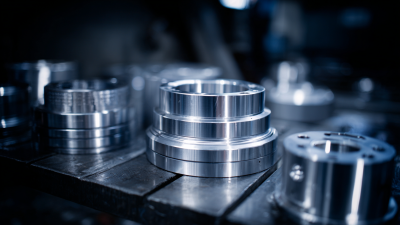

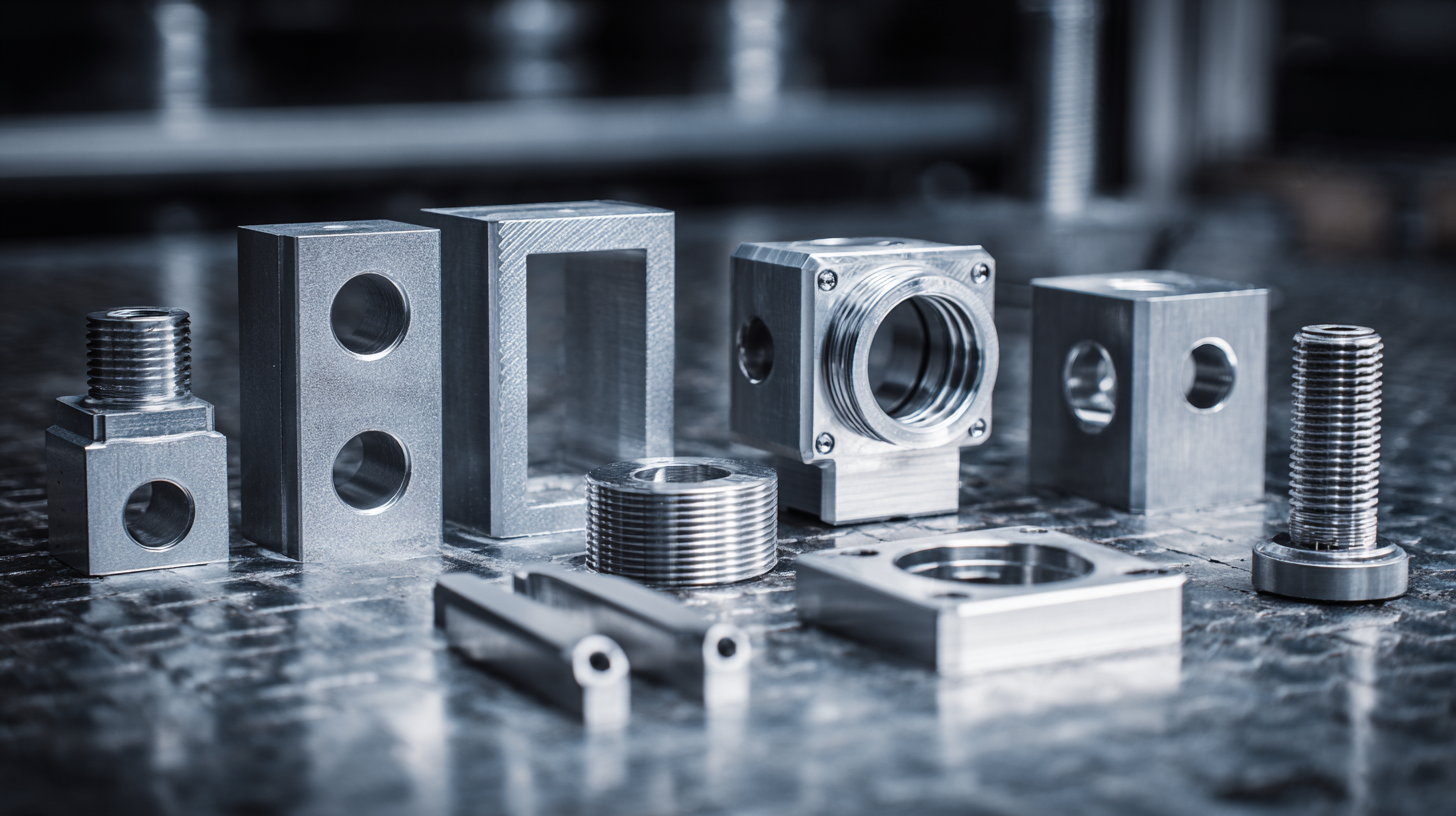

In modern manufacturing, aluminum CNC machining parts are fundamental due to their lightweight, strength, and versatility. These parts can be categorized into several types, each serving specific functions and applications. Common types include

structural components, enclosures, and precision fixtures. Structural components, such as brackets and frames, provide essential support and load-bearing capabilities in assembly processes. Enclosures, like housings for electronic devices, protect sensitive equipment while also offering aesthetic benefits.

Another critical category is precision fixtures, which are used to hold parts in place during machining operations. These fixtures are specially designed to ensure high accuracy and repeatability, essential for producing high-quality products. Additionally, specialized parts like heat sinks and custom machined components play a vital role in the efficiency and performance of various systems. Understanding these fundamental types of aluminum CNC machining parts not only empowers manufacturers to make informed choices but also enhances the overall production quality and efficiency in the manufacturing landscape.

Aluminum CNC machining has emerged as a pivotal process in the aerospace and automotive industries, where precision, weight reduction, and durability are paramount. According to recent industry analysis, the global CNC machining market is projected to reach $100 billion by 2025, with aluminum components playing a crucial role in this growth. The lightweight nature of aluminum, combined with its excellent strength-to-weight ratio, makes it an ideal choice for aerospace applications, where every gram matters. For instance, components such as aircraft skins, frames, and brackets are increasingly being produced using aluminum CNC machining techniques to enhance fuel efficiency and performance.

In the automotive sector, the demand for aluminum parts is on the rise, driven by the push for more fuel-efficient vehicles and electric cars. Forecasts suggest that the use of aluminum in automotive manufacturing could surpass 20 million tons by 2025. The precision provided by CNC machining allows for complex designs that improve aerodynamics and reduce overall vehicle weight. Furthermore, the ability to produce highly intricate components with tight tolerances ensures that parts fit seamlessly, which is essential for both vehicle performance and safety standards. Consequently, the adoption of advanced metal fabrication technologies, particularly in machining, is instrumental in meeting the evolving demands of these industries.

In modern manufacturing, the precision of aluminum CNC machined components is significantly influenced by the tolerances and specifications set throughout the production process. According to a report by the National Institute of Standards and Technology (NIST), components created with tight tolerances, often within ±0.005 inches, demonstrate a 15-20% increase in performance efficiency compared to those with looser specifications. This level of precision is crucial in industries such as aerospace and automotive, where even the slightest deviation can lead to failures in critical systems.

Moreover, understanding and applying appropriate tolerances can help manufacturers optimize material usage and reduce waste. The Machining Industry Association (MIA) highlights that 30-40% of production costs are linked to inefficiencies in machining processes, including parts that do not meet specification requirements. By prioritizing precise tolerances, manufacturers can not only enhance the reliability of their aluminum components but also drive down costs associated with rework and scrap. This approach is particularly vital given the escalating demand for lightweight, high-strength materials in competitive markets.

| Part Name | Material | Tolerances (mm) | Dimensions (mm) | Surface Finish |

|---|---|---|---|---|

| Bracket A | Aluminum 6061 | ±0.05 | 100 x 50 x 5 | Anodized |

| Plate B | Aluminum 7075 | ±0.02 | 150 x 75 x 10 | Brushed |

| Housing C | Aluminum 5052 | ±0.03 | 200 x 100 x 20 | Powder Coated |

| Bracket D | Aluminum 2024 | ±0.01 | 80 x 40 x 4 | Anodized |

| Component E | Aluminum 6063 | ±0.05 | 120 x 60 x 15 | Mill Finish |

The cost-effectiveness of aluminum CNC machining compared to other materials is a key consideration in modern manufacturing. Aluminum, known for its lightweight nature and excellent machinability, offers significant advantages over traditional materials like steel. The reduced weight associated with aluminum components contributes directly to improvements in fuel efficiency and performance, particularly in the automotive and aerospace sectors, where every ounce matters. Moreover, the machining process for aluminum is often simpler and requires less tool wear, leading to decreased production costs and shorter lead times.

In contrast, while magnesium alloys present benefits in specific applications due to their even lower density, they can entail higher processing costs and specific handling requirements that may not justify their use in all scenarios. Additionally, the initial investment for machinery adapted to work with these alloys can be steep. Therefore, evaluating the economics of material selection reveals that aluminum CNC machining frequently emerges as the more cost-effective choice, aligning with industry goals of innovation and sustainability while maintaining quality and precision in manufacturing processes.

As the manufacturing industry evolves, aluminum CNC machining is experiencing a transformational shift driven by innovative technologies and a growing emphasis on sustainability. Advances in machining technology, such as the integration of artificial intelligence and machine learning, enable manufacturers to optimize processes, reduce waste, and enhance precision. These innovations not only contribute to improved productivity but also ensure that aluminum parts can be produced with higher efficiency and lower energy consumption.

Sustainability initiatives are increasingly at the forefront of aluminum CNC machining, addressing environmental concerns associated with production. Industry leaders are adopting closed-loop systems that recycle scrap material generated during machining, significantly minimizing waste. Furthermore, the shift towards eco-friendly lubricants and cutting fluids reflects a commitment to reducing environmental impact. As manufacturers invest in these sustainable practices, they are not only meeting regulatory requirements but also appealing to a growing consumer base that values green manufacturing processes. This alignment of innovation and sustainability is set to define the future of aluminum CNC machining, ensuring its viability in an ever-competitive market.