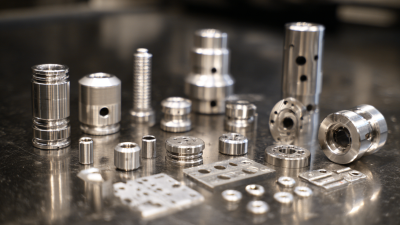

Choosing the right Aluminum Parts for any project can be daunting. The aluminum industry is vast, and selecting suitable components can impact performance significantly. According to a recent report by Market Research Future, the aluminum market is expected to grow by 5% annually. This growth indicates the increasing demand for high-quality aluminum components in various applications.

John Smith, an industry expert with over 20 years of experience, states, "Selecting the right aluminum parts can either make or break your project's success." This highlights the importance of careful consideration during the selection process. Quality, strength, and weight are critical factors that need evaluation. Each project can have unique requirements that don't always align with standard offerings.

Consideration must also be given to sourcing and manufacturing processes. Some suppliers may offer lower prices, but those parts might lack reliability. Ultimately, the decision should focus on long-term value rather than initial cost. Balancing quality with budget constraints poses a challenge that many face. Reflecting on these factors is vital for ensuring the project's success and longevity.

When selecting aluminum parts, understanding the different types of aluminum alloys is crucial. Aluminum alloys are categorized into series based on their primary alloying elements. Commonly, there are two main groups: wrought and cast alloys. Wrought alloys, often found in structural applications, offer excellent strength and versatility. Their numbers typically start with a “1” to “8,” denoting various properties and uses.

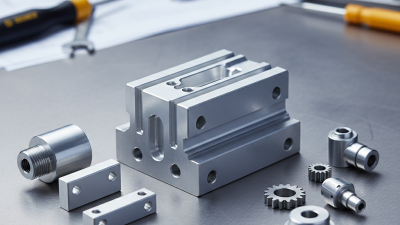

For example, 6061 aluminum, a popular wrought alloy, excels in corrosion resistance. It’s often used in automotive and marine applications. With good machinability, this alloy is easy to work with, making it a go-to choice for engineers. According to recent data from industry reports, 6061 accounts for a significant percentage of aluminum alloy exports, highlighting its widespread acceptance.

On the other hand, cast alloys are usually denoted by a four-digit code, such as A356. This alloy features excellent fluidity and is often used in complex shapes. However, they can be more brittle than wrought alloys. Choosing between these options hinges on project requirements. It's vital to reflect on specific stresses and environmental conditions each alloy may face. A mismatch could lead to structural failures, costing time and resources.

When assessing the strength and durability requirements for aluminum parts, it's crucial to consider specific project needs. Aluminum alloys vary widely in strength. For instance, 6061-T6 can withstand significant stress, with a yield strength of 275 MPa. This makes it suitable for structural applications. However, while strong, it can be susceptible to corrosion if not properly treated.

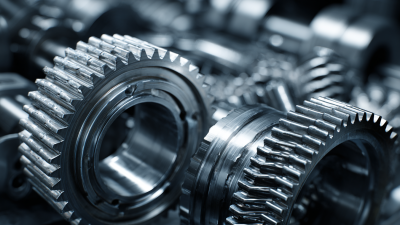

Durability also depends on the environment. For instance, marine applications require materials that resist saltwater corrosion. According to industry reports, the cost of corrosion in the U.S. is estimated at around $276 billion annually, stressing the importance of using appropriate alloys. Sometimes, even slight miscalculations in alloy choice can lead to failure in real-world applications. Projects in harsh conditions might need extra coatings for protection, raising both complexity and costs.

Weight considerations also play a role in selection. A lighter part can improve overall project efficiency but may compromise strength. Finding the balance is often challenging. It's essential to review design specifications and stress factors carefully. Many designers overlook the actual application conditions. Testing prototypes can reveal unforeseen weaknesses, essential for project success.

When evaluating the cost-effectiveness of aluminum parts, it’s essential to consider various factors. The type of aluminum alloy plays a significant role in pricing. Some alloys are more expensive due to their properties. For instance, aircraft-grade aluminum might cost more than basic structural aluminum, yet it may offer superior strength and lighter weight.

**Tip:** Assess your project needs carefully. Sometimes, a less costly option may suffice without compromising quality. Look for the balance between cost and performance.

Furthermore, think about the quantity required. Bulk purchasing can lead to discounts. However, unnecessary overage might inflate costs. It’s crucial to estimate accurately how many parts you’ll need.

**Tip:** Do not rush your calculations. Double-check your figures. An error could lead to wastage and unexpected expenses.

Lastly, remember to factor in shipping and handling costs. These expenses can add up, especially for larger shipments. Be aware of potential delays as they could impact your project's timeline. Keeping communication open with suppliers might help mitigate issues.

When selecting aluminum parts, it's vital to consider weight and density. Aluminum is lightweight, making it ideal for many applications. The density of aluminum is about 2.7 g/cm³, significantly lower than steel. This difference can affect the overall weight of a project. Lighter parts contribute to ease of use and can improve energy efficiency.

However, lighter materials may have different strength characteristics. They might not always be suitable for heavy-duty applications. Designers must balance weight with structural integrity. For instance, an aircraft component needs to be lightweight but also strong enough to withstand stresses. Sometimes, using a heavier material is warranted. Reflecting on the requirements of the project helps make informed decisions.

Additionally, consider how aluminum's weight impacts the user experience. A vehicle with lighter parts may have better acceleration and fuel efficiency. Yet, if users want durability, options may narrow. Choosing the right aluminum parts requires careful thought. Mistakes in weight considerations can lead to failures down the road. Always test prototypes before finalizing designs.

When selecting aluminum parts, surface treatment is key. Different treatments yield diverse outcomes in appearance and durability. Anodizing is popular for its ability to enhance corrosion resistance. It creates a thicker oxide layer, which also improves wear resistance. This process is not flawless, though. Variations in thickness can occur, affecting the final color.

Another option is powder coating. This technique provides a wide range of colors and finishes. It achieves a more vibrant look, making aluminum parts stand out. However, the coating can chip or fade over time. The final surface quality can depend on the application process and environmental conditions. Consistency is crucial but not always guaranteed.

Additionally, chemical conversion coatings offer a unique benefit. They improve adhesion for paints and other coatings. However, they provide minimal physical protection. It's essential to consider the specific needs of your project when selecting a treatment. Each method has its advantages and imperfections, which can influence performance and aesthetics. Understanding these details is vital for making the right choice.

| Surface Treatment | Description | Benefits | Common Applications |

|---|---|---|---|

| Anodizing | An electrochemical process that thickens the natural oxide layer on the surface of aluminum. | Increased corrosion resistance, improved wear resistance, non-conductive surface, and aesthetic finish. | Aerospace, automotive, and architectural applications. |

| Powder Coating | A dry finishing process where a powdered paint is applied electrostatically and then cured under heat. | Durable finish that is resistant to chipping, scratching, and fading while providing a variety of colors. | Furniture, outdoor equipment, and automotive parts. |

| Chemical Conversion Coating | A chemical treatment that adds a thin layer of corrosion-resistant material to the metal surface. | Good corrosion resistance and provides a surface for better paint adhesion. | Military applications, electronic components, and architectural applications. |

| Electrocoating | A process where paint is applied using an electric charge, allowing the coating to reach complex shapes. | Even coating thickness, excellent corrosion resistance, and good durability. | Automotive and appliance industries. |