In today's manufacturing landscape, the demand for precision and efficiency continues to drive innovation, particularly in the realm of CNC machined aluminum parts. According to a recent report from MarketsandMarkets, the global CNC machining market is projected to reach $100.2 billion by 2025, with aluminum components playing a pivotal role due to their lightweight yet durable characteristics. As industries ranging from aerospace to automotive increasingly rely on custom machined parts, understanding how to select the right CNC machined aluminum components becomes critical for project success. This blog will guide you through the essential factors to consider when choosing these parts, ensuring that your project meets both efficiency and performance standards while leveraging the advantages of aluminum machining.

When selecting CNC machined aluminum parts, it's crucial to understand the various types available to ensure they align with your project requirements. CNC machining offers a range of aluminum alloys, each with distinct properties and uses. For instance, 6061 aluminum is known for its versatility and excellent corrosion resistance, making it ideal for structural components and automotive applications. Conversely, 7075 aluminum, renowned for its high strength-to-weight ratio, is preferred in aerospace applications where performance is paramount.

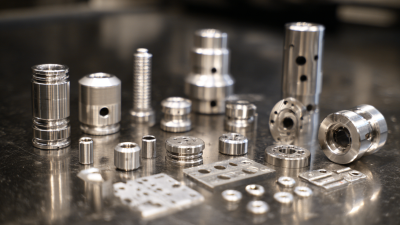

In addition to the alloy types, the intended function of the parts can dictate which CNC machining methods to use. Common options include milling, turning, and laser cutting, each suited for different geometries and tolerances. For complex shapes, precision milling may be the best choice, while turning might be optimal for cylindrical components. Understanding these types and their applications allows engineers and designers to make informed decisions, ensuring their projects not only meet specifications but also achieve the desired performance and durability.

When selecting CNC machined aluminum components for your project, several key factors should be considered to ensure optimal performance and cost-effectiveness. First and foremost, understanding the specific requirements of your project is critical. This includes the intended application, load conditions, and environmental factors that may affect the performance of the aluminum parts.

Tip 1: Consider the alloy type that best suits your needs. Different aluminum alloys offer various strengths, corrosion resistance, and machinability. For example, 6061 and 7075 are popular choices; 6061 is known for its versatility, while 7075 offers higher strength, making it ideal for demanding applications.

Tip 2: Pay attention to the machining process. The accuracy of the CNC machining process can greatly influence the final quality of the parts. Evaluate the capabilities of the CNC machinery and the expertise of the operators involved, as precision is essential in achieving the desired specifications without significant rework.

Additionally, analyzing the cost implications of design choices and the manufacturing process can lead to savings and efficiency improvements. Remember to balance quality and cost to ensure the selected components meet both performance and budgetary constraints.

When embarking on a CNC project, understanding the material specifications is crucial for the success and functionality of the final product. Aluminum is a popular choice due to its lightweight nature, corrosion resistance, and excellent machinability. However, not all aluminum alloys are created equal. Depending on your project's requirements, you may need to consider factors such as strength, thermal conductivity, and even aesthetic appeal. Popular alloys like 6061 and 7075 offer different benefits, with 6061 being ideal for moderate strength and weldability, while 7075 is preferred for high-stress applications due to its superior strength characteristics.

Additionally, the tolerances and surface finishes associated with CNC machined aluminum parts can significantly impact the performance of your components. Tight tolerances are essential for parts that fit within complex assemblies, while specific surface finishes can enhance both durability and appearance. Whether you need anodized surfaces for added protection against wear and corrosion or finer finishes for aesthetic purposes, specifying these characteristics from the outset can help streamline the production process and reduce the need for costly revisions. Ultimately, a thorough understanding of material specifications enables you to make informed decisions that align with your project's goals and enhance overall quality.

When selecting CNC machined aluminum parts for your project, customization is key to achieving optimal results. Tailoring these components to suit your specific requirements can significantly enhance functionality and performance. Start by identifying the unique specifications your project demands, such as tolerance levels, surface finish, and dimensional accuracy. Manufacturer capabilities vary, so choosing a supplier that offers comprehensive customization options can make a significant difference.

In addition to standard dimensions, consider how custom features, such as holes, slots, or complex geometries, can be integrated into your aluminum parts. The right CNC machining process allows for intricate designs that are not only aesthetically pleasing but also improve usability. Investing time in discussing your customization needs with your manufacturer may lead to innovative solutions and better products, ultimately ensuring that your machined aluminum parts align perfectly with your project goals.

When it comes to CNC machined aluminum parts, budgeting is a critical aspect that can significantly impact your project's success. Striking the right balance between cost and quality is essential to ensure that you receive product longevity and performance without overspending. Understanding your specific requirements and setting a budget that allows for some flexibility can lead to better purchasing decisions.

Tip 1: Before diving into the market, conduct thorough research to compare the costs of various manufacturers. Pay attention not just to the price, but also the reputation of the supplier. Sometimes, opting for a slightly higher price can result in superior quality and service, ultimately saving you money in the long run.

Tip 2: Consider the implications of choosing lower-cost options. While it may seem economical initially, inferior quality can lead to greater expenses due to rework, replacements, or potential project delays. Therefore, make quality a priority and allocate your budget to reputable CNC machining services that provide good materials and craftsmanship.

Tip 3: Don't forget to factor in additional costs such as shipping and lead times. Sometimes, a supplier with a higher base price may offer faster turnaround times or lower shipping costs, making it a more cost-effective option overall. Analyzing these elements ensures that your budget aligns well with the quality and timeline of your CNC machined aluminum parts, contributing to the ultimate success of your project.