In recent years, Machined Aluminum Parts have become increasingly vital in modern engineering applications, owing to their unique combination of strength, lightweight properties, and resistance to corrosion. According to a report by Grand View Research, the global aluminum market is expected to reach $210 billion by 2025, highlighting the material's growing significance across various industries, including aerospace, automotive, and electronics. The use of precision machining techniques facilitates the production of components that meet stringent quality and performance standards, which is essential as industries seek to enhance efficiency and reduce weights in their designs. Furthermore, a study by the Aluminum Association reveals that aluminum components can result in energy savings of up to 50% in automotive manufacturing, illustrating the substantial advantages that Machined Aluminum Parts offer. This introduction explores the myriad benefits of utilizing these parts, emphasizing their critical role in driving innovation and sustainability in engineering practices today.

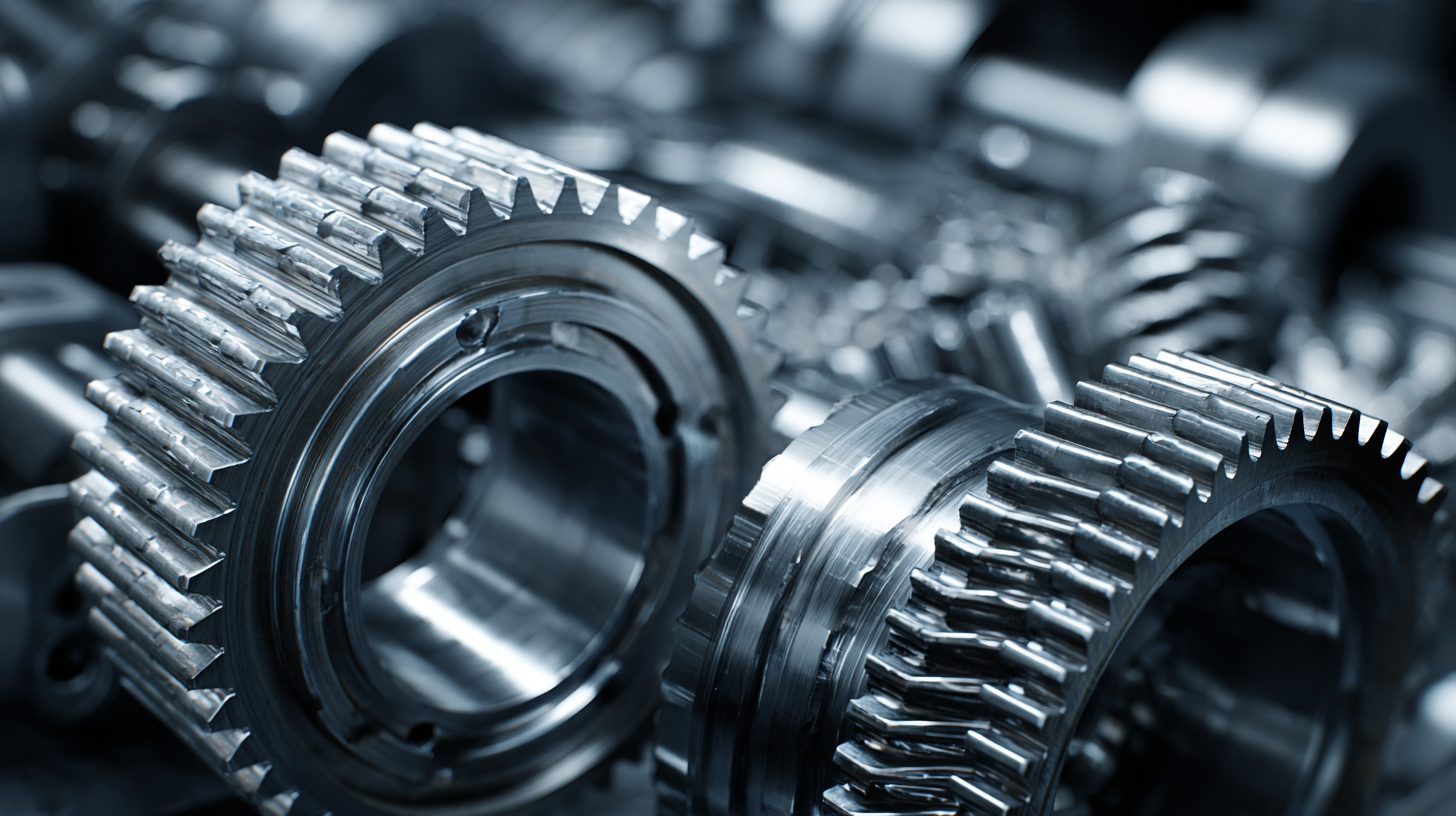

Aluminum machining has evolved significantly over the past few decades, driven by advancements in technology and a growing demand for precision in engineering applications. According to a report by the MarketsandMarkets research firm, the global aluminum machining market is projected to reach USD 10.77 billion by 2026, growing at a CAGR of 5.8% from 2021. This growth can be attributed to improved machining techniques that enhance the efficiency and effectiveness of aluminum processing. Techniques such as high-speed machining (HSM) and computer numerical control (CNC) machining are now commonplace, allowing for intricate designs and superior finishes that were previously unattainable.

Aluminum machining has evolved significantly over the past few decades, driven by advancements in technology and a growing demand for precision in engineering applications. According to a report by the MarketsandMarkets research firm, the global aluminum machining market is projected to reach USD 10.77 billion by 2026, growing at a CAGR of 5.8% from 2021. This growth can be attributed to improved machining techniques that enhance the efficiency and effectiveness of aluminum processing. Techniques such as high-speed machining (HSM) and computer numerical control (CNC) machining are now commonplace, allowing for intricate designs and superior finishes that were previously unattainable.

Moreover, the introduction of new cutting tools and coatings has further refined aluminum machining processes. For instance, the use of carbide and ceramic cutting tools has shown to improve tool life and reduce overall machining costs. A study by the International Journal of Advanced Manufacturing Technology highlights that the right choice of tool materials can increase machining productivity by up to 35%. This evolution not only boosts production rates but also plays a crucial role in meeting stringent quality standards in industries such as aerospace, automotive, and electronics, where the lightweight nature and durability of aluminum make it an essential material.

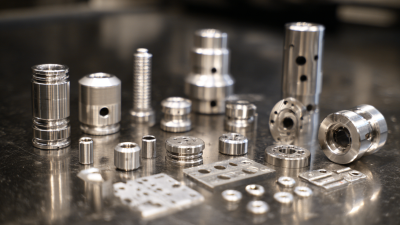

Machined aluminum parts are increasingly favored in modern engineering applications due to their lightweight yet robust nature, providing significant advantages across various industries. One of the key benefits is their high strength-to-weight ratio, making them ideal for sectors such as automotive and aerospace, where efficiency and performance are critical. For instance, the rise of billet aluminum engine blocks in motorsport showcases the capability of these components to handle higher power levels without compromising structural integrity.

Additionally, precision in manufacturing is paramount, and machined aluminum parts can be produced using advanced methods like Coordinate Measuring Machines (CMMs) that ensure exact dimensions and quality control. This precision is crucial for high-performance applications, where even minor discrepancies can lead to significant performance issues.

Tip: When selecting machined aluminum parts, consider the specific environmental conditions they will face, such as temperature and corrosion exposure, to ensure optimal material choice.

Another advantage of adopting aluminum in manufacturing is its compatibility with automation technologies. As the automotive industry increasingly turns to automation to combat rising labor costs, the integration of aluminum components allows for smoother, more efficient production processes.

Tip: Incorporating modern automation solutions can enhance the production efficiency of aluminum parts, but ensure that proper training is provided for personnel to leverage these technologies effectively.

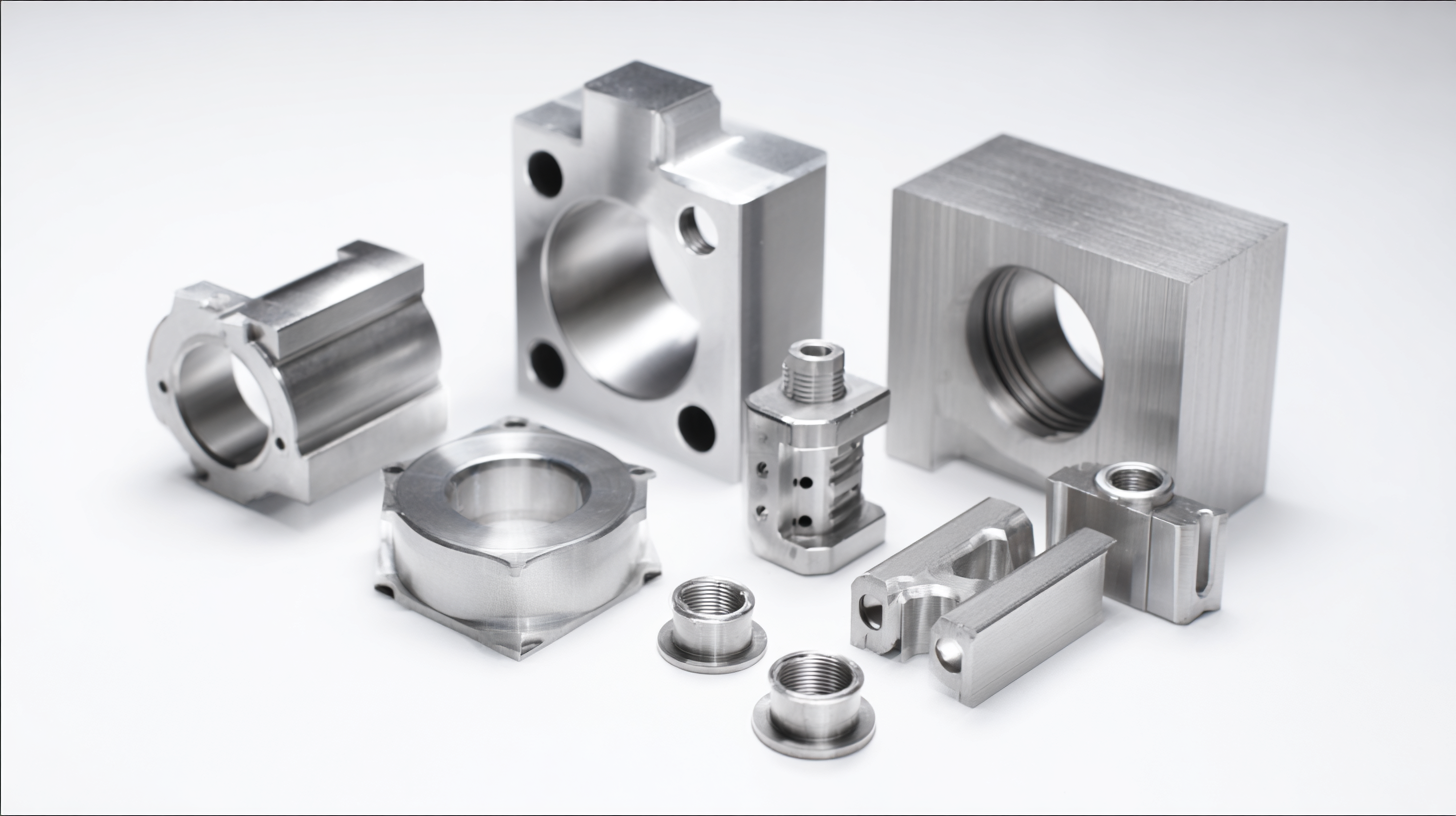

When evaluating materials for engineering applications, aluminum often stands out due to its unique combination of properties. Compared to steel, aluminum parts are significantly lighter, which can enhance overall system efficiency, particularly in industries like aerospace and automotive where weight reduction is critical. While steel provides superior strength and durability, the added weight can be a disadvantage in applications where performance is paramount. Moreover, aluminum boasts excellent corrosion resistance, making it preferable in environments prone to moisture and chemical exposure.

In comparison to plastics, aluminum is more robust and can tolerate higher temperatures without deforming. While plastics offer versatility and are cheaper, their mechanical properties can limit their use in demanding applications. Additionally, aluminum can be alloyed with various elements to improve its properties further, providing engineers with a customizable material that can meet specific performance criteria. Ultimately, the choice between aluminum and other materials hinges on the specific requirements of the application, balancing factors like weight, strength, cost, and environmental resistance.

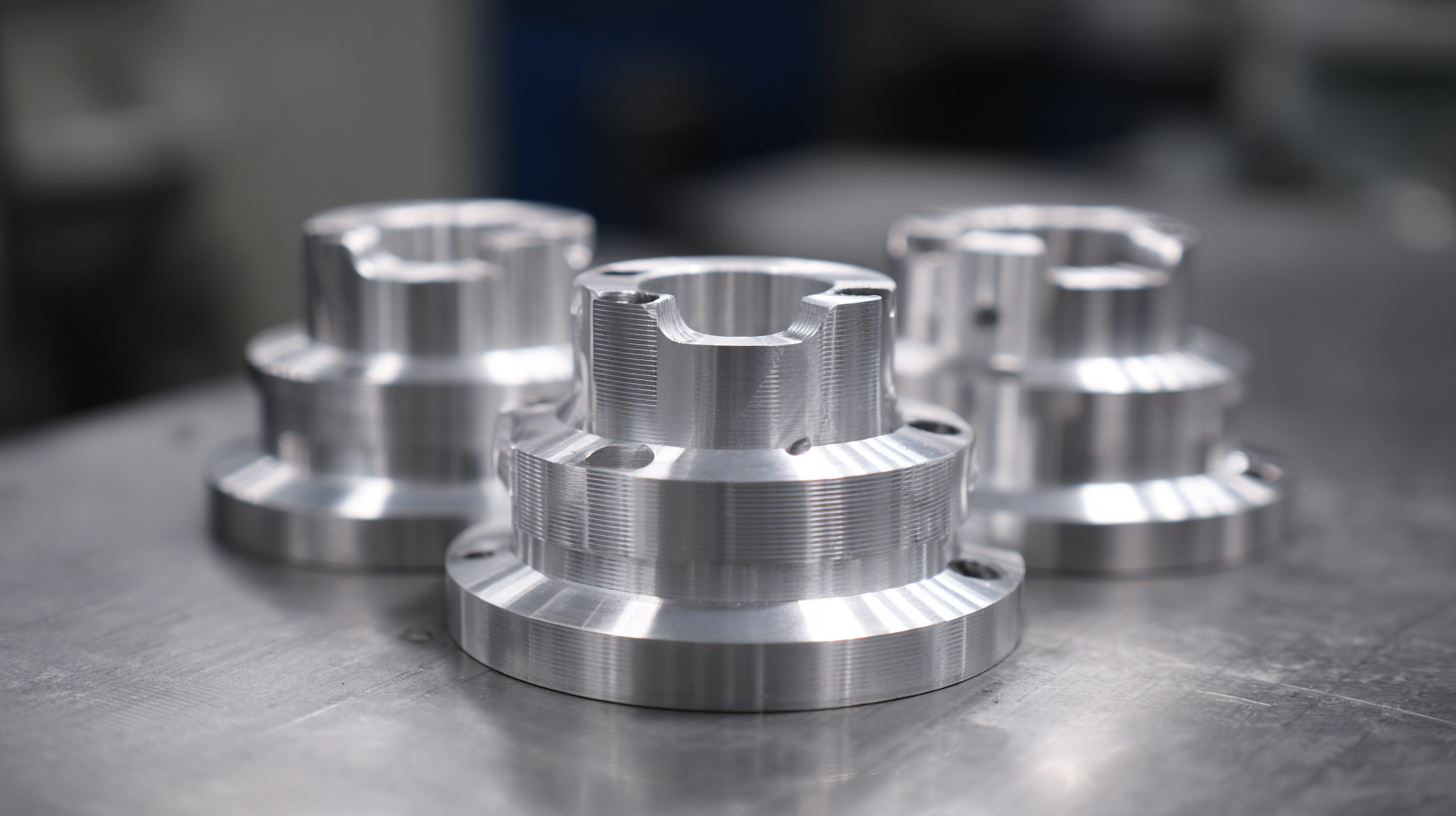

Aluminum components are making significant strides in both the aerospace and automotive industries, thanks to their

lightweight nature and high strength-to-weight ratio.

In aerospace applications, machined aluminum parts contribute to aircraft efficiency, helping to reduce fuel consumption

and emissions while maintaining structural integrity. For instance, aluminum alloys are used extensively in airframes

and engine components, where weight reduction directly correlates with enhanced performance and lower operational costs.

In the automotive sector, the trend towards lightweight materials has driven the adoption of machined aluminum

parts for critical components, including chassis and structural elements. The automotive industry increasingly

leverages aluminum to meet stringent fuel efficiency standards and to support the shift towards electric vehicles.

Tips: When considering aluminum for your next project,

explore various product forms like sheets, wires, and pastes to find the most suitable option for your specific needs.

Additionally, staying informed about the latest advancements in aluminum additive manufacturing can open up new

avenues for innovation within your designs. Finally, prioritize collaboration with suppliers who specialize in

aluminum brazing to ensure optimal performance and durability in your applications.

The advent of 3D printing technology has revolutionized the production of machined aluminum parts, offering unprecedented opportunities for innovation in modern engineering. Traditional machining processes are often time-consuming and costly, but with 3D printing, complex geometries can be fabricated quickly and efficiently. This shift not only reduces lead times but also allows for the creation of lightweight components that maintain high strength and durability, essential for sectors such as aerospace and automotive engineering.

Looking toward the future, the integration of advanced materials and additive manufacturing techniques is expected to further enhance the capabilities of machined aluminum parts. Innovations like hybrid manufacturing—combining 3D printing with traditional machining—are on the rise, enabling engineers to optimize performance and material utilization. Furthermore, as market demand for customized products increases, 3D printing will provide the flexibility needed to tailor designs to specific applications, thereby driving progress in functional prototyping and production scalability.

| Feature | Benefit | Application | Future Trends with 3D Printing |

|---|---|---|---|

| Lightweight | Reduces energy consumption and improves efficiency | Aerospace components | Integration with additive manufacturing for complex geometries |

| Corrosion Resistance | Lowers maintenance costs | Automotive parts | Utilization of new coating techniques in 3D-printed parts |

| High Strength-to-Weight Ratio | Allows for thinner walls while maintaining strength | Sports equipment | 3D printing enabling on-demand production of lightweight components |

| Thermal Conductivity | Enhances heat dissipation for electronic devices | Heat sinks | Additive manufacturing to create custom thermal management solutions |

| Customization | Facilitates rapid prototype development | Robotics | Personalized designs possible through advanced 3D printing techniques |